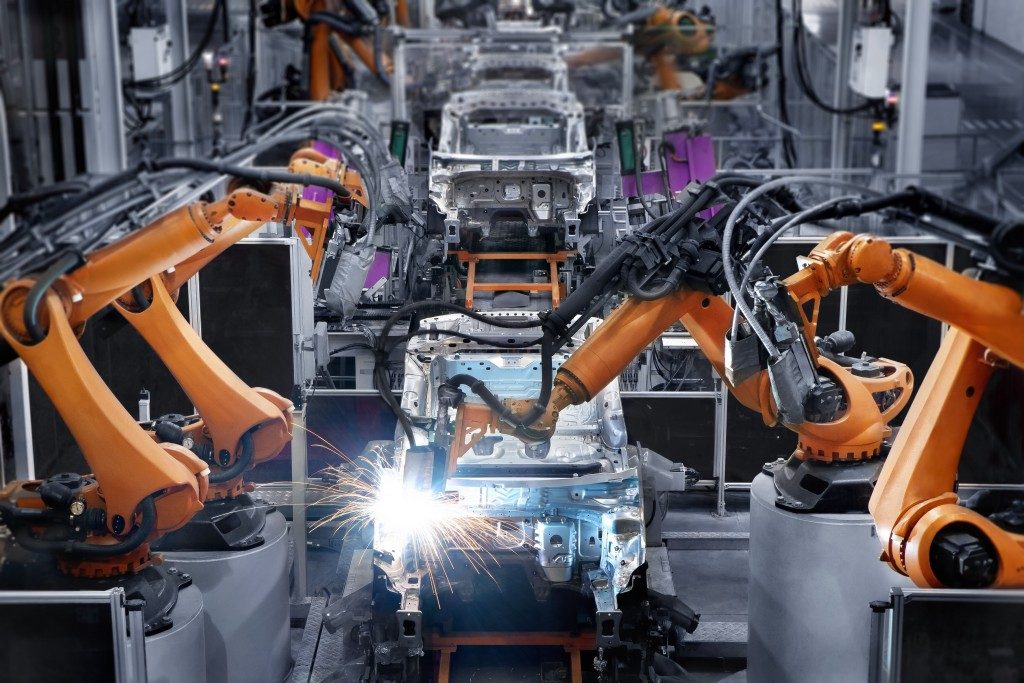

Perhaps one of the industries whose workplace is prone to a lot of safety risks is manufacturing. With all the tools and machines, there are posed different hazards that could compromise the safety of anyone who walks in the factory, most especially to the employees who spend day in and day out in the area.

Safety and risk prevention protocols must always be followed in manufacturing sites. It pays to have every employee aware of how to keep themselves safe in the workplace. Here are some safety tips in manufacturing sites.

Inform people in charge of potential safety hazards

Every employee has to do their part. Instead of relying on the supervisors and managers to inspect the area and come up with safety measures, they should actively take part in making the workplace a safer environment for everyone. It could be as simple as making a check of their station every day, or immediately informing those in charge in case any safety hazard is noticed.

Use tools with care

A typical workplace in a manufacturing company is bound to be filled with tools and machinery. A common cause of injuries in a factory is the mishandling of tools. Imagine how much damage a single sharp object can do if not handled correctly.

Even if the employees know what they’re doing, everyone should be trained on how to handle the different tools and machinery inside the factory — from advanced tools like diaphragm pumps to the most basic equipment like drills, etc. Educating and informing everyone on how each tool is used will go a long way in keeping the workplace safe.

Always wear safety equipment

Especially if they’ve been working there for a while, employees may start to get comfortable and neglect to wear their safety gear. But just because an accident hasn’t happened for the longest time, doesn’t mean that there’s no possibility of one in the future. With that, employees have to be equipped at all times.

Simply wearing safety equipment and adhering by safety protocols will do a lot in terms of keeping the employees safe. There’s a reason these rules are in force, so everyone should be doing their part in abiding by them.

Know where to go and what to do in case of emergencies

The last thing anyone wants during an emergency is chaos. For example, when a fire breaks out, there’s a high chance that everyone will panic and make the situation worse. But panic and chaos can be prevented by educating people on the dos and don’ts in case of an emergency.

The fire exits must be marked, and everyone should know about it. The procedure of exit should also be laid down. It’s ideal to hold a drill for natural calamities such as fire, earthquakes, etc. to equip everyone in case the situation arises.

Don’t be negligent

If you look at workplace accidents that can happen, you’ll see that they stem from some sort of negligence. For example, an employee slips because of a wet surface. That may be caused by someone negligent in cleaning up spilled liquid.

The ultimate key to making the workplace a safer environment for everyone is by not being negligent. Always clean up after yourself, pile the boxes or other heavy materials properly to prevent falls, don’t leave any tool or machinery unattended.

A manufacturing workplace can be a dangerous place. But if everyone does their part in keeping the environment safe, then a lot of safety hazards and dangers can be prevented.