Tall buildings present a unique challenge in bringing up materials quickly. Tower cranes, freight lifts, and specialised containers like lifting cages play a key role in maximising the efficiency of high-rise building construction.

One of the continuing challenges of major construction projects today is the need to hoist massive amounts of construction equipment and material across great heights. As the structures of today become taller and taller, the demands for hauling construction supplies to the heights they are needed to grow ever more challenging.

In the past, cranes were built along the sides of the buildings, allowing construction workers and foremen to bring steel beams atop the structures. These are still commonly used in supertall skyscrapers. Lighter weights such as toolboxes are also sometimes brought up through lifts within the buildings themselves. Many large structures today are also built with tower cranes, which hoists up massive amounts of construction material from the ground to the tallest floor of the structure.

Hoist Them Higher

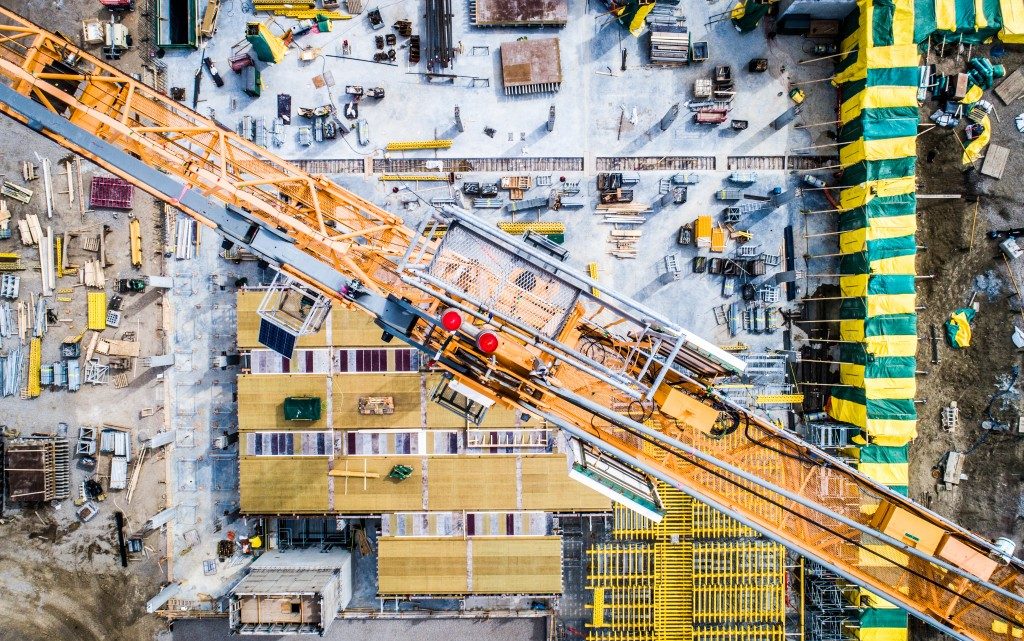

Tower cranes are a familiar sight in construction sites across the globe. They provide builders with a means to lift materials to a degree of speed that far exceeds the capacity of pulleys and cranes hoisted from the building itself. Cranes this size also enables builders to hoist up machinery and tools up several hundred meters above ground without taxing the weight limits of the lifts.

To the casual observer, the tower crane is a paradox unto itself. How does a structure as large as this get so tall without the need for an equally large crane to build them in turn? The answer lies in the hydraulic mechanisms within the crane’s base. After being assembled to a certain height on the ground by a mobile crane, the tower crane relies on a climbing frame to add new sections, allowing it to rise alongside the building it builds.

Up the Lift

Lifts are what made the skyscraper practical. The first practical lifts allowed cities across the United States to grow exponentially tall. Today’s construction crews rely on lifts carrying personnel and light equipment across the height of the building. A temporary lift is usually built into the side of the structure to facilitate the movement of equipment and crew up and down the skyscraper as its built.

Construction lifts can usually carry a fair amount of lightweight freight, which can usually be carried by trolleys.

Lifting Cages

Alternately serving as a convenient storage tool and a defensive measure against theft, lifting cages are a common way of storing and transporting construction equipment and supplies and can be brought in by cranes and forklifts for use in the construction site. Lifting cages can contain several items at once; they can possess features such as shelves and rigging bars that would allow them to store and carry boxes and cords, respectively.

Besides safeguarding tools and items against theft, lifting cages can allow builders to bring massive amounts of items effectively to their construction sites with relative ease, streamlining the need to haul tools to the desired location in a construction site. The heavy-duty metal framework makes them ideal for use in construction settings. These lifting cages have provisions that would allow them to be hoisted to their desired location via crane and be carted around by trolleys and forklifts.